Thanks to major innovations in the development of sophisticated resins and the improvement in their material properties, foam injection molding has increasingly become an option for manufacturers and designers looking to develop ahead-of-the curve products.

In particular, XL EXTRALIGHT® foam injection molding, developed with exclusive closed-cell foam injection molding technology and polyolefin resins, is ideal for a multitude of applications that require superior quality and durability. Lightweight, easy to clean, 100% waterproof and chemical-resistant, XL EXTRALIGHT® self-skinning foam is perfectly suited for consumer goods, components in the transportation industry and equipment in the medical industry.

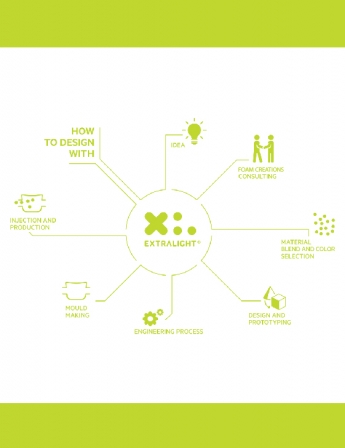

Kicking off a project to develop a product using XL EXTRALIGHT® foam injection molding often entails a 6-step process with the manufacturer, Foam Creations. Let’s take a look at this process and why each are so important to achieving a product that meets your criteria.

- 1. Initial meeting with Foam Creation’s project team: The first initial step is to sit down with the designer and engineers to describe the vision of your product, why you deem foam injection molding is the best fit, your specific design and performance criteria, production volume and timeline.

- 2. Material blend and color selection: When it comes down to using XL EXTRALIGHT® foam injection molding for a product, there are myriad of possibilities with respect to its material properties, such as durability, rigidity, geometry, etc. Each project usually entails a distinct material blend that will meet your requirements. In addition, you can choose any type of foam color based on your brand strategy or overall design concept.

- 3. Initial prototype: Once the specs are honed out, you have one of two options. Foam Creation’s design team can create an initial 3D model or can revise the CAD designs developed by your in-house design team. In many cases, a foam prototype will be created to validate the design’s functionality.

- 4. Engineering process: As soon as your foam injection molding prototype has been fine-tuned, both engineering teams—yours and ours—will thoroughly validate the cross-linked foam prototype. Engineering verification tests (EVTs), which include engineering, design and production validations, are conducted. Issues are then rectified in the 3D CAD files and subsequent prototypes are produced for further testing. This is a rigorous, iterative process to ensure that the product can be consistently manufactured at scale and based on your quality standards.

- 5. Mold making: When the engineering process is completed, Foam Creations’ team manufactures the mold using a unique blend of alloy materials. Proper tooling is critical as it reduces the chances of poor product quality, part failure and other manufacturing errors. What’s more, the mold’s design can be effective in optimizing overall cycle times.

- 6. Injection and Manufacturing: The final step in your project is the high-volume production of your product made with EVA foam injection molding. A first production batch may be manufactured as part of an in-line quality control process. Depending upon volume levels, products made with closed-cell foam can be produced in very short timeframes, thanks to Foam Creations’ high manufacturing capacity and round-the-clock production.

As you can see, regardless of the complexity of your foam injection molding product, Foam Creation’s manufacturing workflows leverages the impressive material properties of XL EXTRALIGHT® to design quality and durable products. Fostering innovation, collaboration and efficiency, our project team will help you make the most out of our next-generation crossed-link foam to design solutions that spark demand in your target markets.