The USMCA Advantage: Canada and Mexico as Tariff-Free Gateways for American Businesses

A cornerstone of the strategic advantage offered by North American manufacturing, particularly when partnering with a company like Foam Creations that has facilities in both Canada and Mexico, is the leverage provided by the United States-Mexico-Canada Agreement (USMCA). This agreement, which superseded NAFTA, establishes specific rules of origin and trade facilitation measures among the three member nations. For American companies, having components or finished products manufactured by a USMCA-zone partner like Foam Creations in Canada or Mexico offers a crucial and often decisive advantage: eligibility for tariff-free access when those goods are imported into the United States. While the broader discussions surrounding global trade uncertainties and the general benefits of North American manufacturing are valid, the fact that Canada and Mexico are key USMCA signatories means that goods meeting the agreement's rules of origin, when manufactured by partners like Foam Creations in these countries, can frequently enter the US market without being subjected to the significant tariffs that might apply if the same goods were sourced from manufacturers in other regions like Asia or Europe.

This provides a stable, predictable, and highly competitive cost structure that is often impossible to achieve when relying on sourcing locations outside of major free trade blocs. The ability to manufacture within the USMCA territory is a powerful tool for American businesses seeking to bypass the volatility and financial uncertainties associated with international trade and tariffs. It not only simplifies customs procedures but also provides a clear legal framework for trade, reducing the risk of unexpected duties or trade barriers. By strategically manufacturing in Canada or Mexico with Foam Creations, American companies can effectively optimize their supply chains for both cost-efficiency and resilience, securing tariff-free manufacturing opportunities that directly benefit their bottom line and market position.

Strategic North American Manufacturing: Foam Creations' Solution and Key Benefits

Foam Creations stands as a recognized and experienced leader in North American manufacturing, specializing in advanced closed cell foam production and intricate EVA foam injection molding. With decades of expertise and a proven track record, including historical involvement in revolutionary products like the original Crocs™ sandals (explore our portfolio), our capabilities extend beyond standard foam fabrication. Our strategically located manufacturing presence within North America—with facilities in both Canada and Mexico—positions us perfectly to serve the needs of American companies actively looking to reshoring their operations back to the continent or seeking to diversify their sourcing strategies away from potentially unstable overseas dependencies. We offer a comprehensive suite of services, from design assistance and material selection to tooling and high-volume production.

Partnering with Foam Creations for your critical North American manufacturing needs unlocks a multitude of tangible benefits:

- Significantly Reduced Transportation Costs: Sourcing locally in North America eliminates high shipping costs and minimizes the risks of damage or loss during transit compared to working with overseas suppliers located thousands of miles away.

- Dramatically Faster Lead Times: Our efficient production processes, combined with geographical proximity within North America, allow for significantly faster delivery of components and finished goods. This enhances responsiveness to dynamic market demands and consumer trends. We are equipped to offer rapid service and facilitate just-in-time production strategies that are impractical with lengthy international shipping lanes.

- Increased Manufacturing Flexibility: Our local presence means we can adapt quickly to changes in order volume, product specifications, or design iterations. This provides the operational flexibility needed to scale production up or down efficiently without the constraints imposed by the long communication and shipping channels inherent in foreign manufacturing partnerships. This nimbleness is vital in today's fast-changing market.

- Effective Mitigation of Tariff Risks: By partnering directly with a local North American manufacturer like Foam Creations, you directly address and largely eliminate the financial risks associated with unpredictable international tariffs and evolving trade uncertainties. This helps to stabilize overall costs and provides a clearer financial outlook.

- Lowered Warehousing Costs: Optimized delivery schedules and the ability to receive shipments more frequently and predictably from a nearby North American facility mean businesses can reduce the need for large buffer inventories. This leads to significant reductions in warehousing costs, freeing up capital and space.

- Streamlined Logistics and Minimal Trade Barriers: Enjoy fast delivery and benefit from the minimal taxes and tariffs applicable to goods manufactured and shipped within the North American trade zone, simplifying customs and import processes considerably compared to international shipments.

- Enhanced Quality Control and Collaboration: Proximity allows for closer collaboration throughout the design, prototyping, and manufacturing stages. This facilitates more rigorous quality control, easier problem-solving, and a stronger partnership, leading to higher quality finished products.

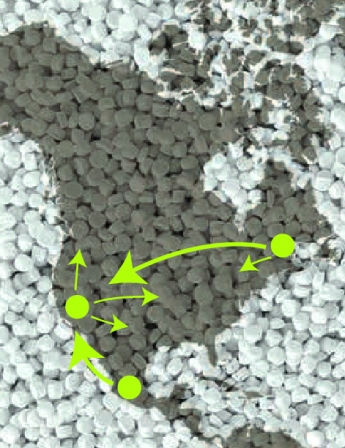

Our specific expertise in EVA foam injection molding, a precision manufacturing process, offers inherent advantages. It yields superior mechanical properties and highly homogenous quality surface areas when compared to less precise processes like compression molding, often used overseas. This injection molding process also typically creates less material waste and allows for much higher definition and crispness in molded logos, textures, and intricate designs. At the core of many of our solutions is our proprietary XL EXTRALIGHT® material. This material is not just any foam; it's a durable, cross-linked closed-cell structure specifically engineered for performance. It boasts exceptional abrasion and chemical resistance, crucial for demanding applications. It offers a wide range of customizable hardness levels while consistently remaining remarkably lightweight, completely impervious to water absorption, and notably easy to clean and maintain – properties that make it ideal for a diverse range of products manufactured right here in North America, from medical devices to consumer goods. Learn more about the unique properties of XL EXTRALIGHT® technology and our range of materials.

Navigating Global Trade Uncertainty with North American Manufacturing

The current global market presents significant challenges and complexities for American companies, prompting an urgent need to reassess and often restructure their reliance on distant, often vulnerable, supply chains. Geopolitical shifts, unexpected events like pandemics, natural disasters, and fluctuating international relations have repeatedly exposed the fragilities inherent in sourcing components and finished goods from across the globe. Businesses, particularly those in demanding and highly regulated sectors such as medical devices, consumer goods, and specialized industrial components, face a unique set of hurdles. These include unpredictably long lead times that hinder responsiveness to market shifts, wildly fluctuating and often exorbitant shipping costs driven by global logistics bottlenecks, inconsistent product quality stemming from varying international manufacturing standards and oversight challenges, the necessity of maintaining high inventory levels as a buffer against delays, and, perhaps most pressingly in the current climate, the increasing burden of international tariffs and trade duties. Experienced North American manufacturers, like Foam Creations, offer solutions to navigate this volatile landscape.

Recent news cycles have been dominated by reports highlighting ongoing trade tensions between major global economic blocs and the tangible potential for the imposition of new and significant duties on imported goods. These include specific discussions around future pharmaceutical tariffs, potential duties impacting consumer electronics, automotive parts, and even less conventional items like foreign-made media. The unpredictable nature of these governmental trade actions, sometimes announced with little warning, adds profound layers of complexity and financial uncertainty to international sourcing strategies. While reports may surface regarding potential phased tariff reductions or negotiations, the overarching environment remains one of instability. This unpredictability makes establishing stable, reliable, and cost-predictable sourcing and manufacturing solutions within closer proximity not just desirable, but a strategic imperative for long-term business health and competitiveness. Embracing a reshoring manufacturing approach or solidifying a robust North American manufacturing strategy, often facilitated by partners specializing in materials like EVA foam injection molding and closed cell foam, offers a direct and effective way to mitigate these pervasive global uncertainties.

The Strategic Advantage of Local Sourcing and Tariff Mitigation

The financial pressure exerted by rising tariffs on imported components can be substantial, directly impacting profit margins and forcing difficult pricing decisions. Furthermore, the constant threat of *new* tariffs or changes to existing trade agreements creates an environment of persistent market uncertainty that complicates business planning and investment. Transitioning your supply chain and manufacturing operations to a local manufacturer in North America is not merely a logistical shift; it is a fundamental strategic move designed to effectively circumvent and mitigate these significant international trade risks. By sourcing and manufacturing locally within the North American free trade zone, companies can leverage established trade agreements like the USMCA to benefit from significantly lower, or even entirely minimal, taxes and tariffs on goods crossing borders within the zone. This offers a distinct and increasingly critical financial advantage over relying on overseas suppliers whose products are heavily impacted by substantial import duties levied by the US or other North American nations. Leading experts in North American manufacturing, such as Foam Creations, are uniquely positioned to help businesses make this transition smoothly and efficiently.

This strategic decision to manufacture domestically or nearshore within North America helps to stabilize production costs, making financial forecasting more reliable and less subject to unpredictable external trade policies. It provides a crucial layer of peace of mind in what remains an unpredictable global market landscape. Beyond tariffs, North American sourcing inherently streamlines logistics, reduces shipping complexities, and shortens transportation routes, all of which contribute to cost savings and enhance overall supply chain resilience. This local presence means faster reactions to unexpected disruptions, whether they are trade-related, environmental, or logistical, ensuring a more robust and reliable flow of necessary components and products to market. Choosing a partner with deep expertise in EVA foam injection molding and closed cell foam in this region provides additional benefits in material performance and design.

| Key Concept | Benefit / Description |

|---|---|

| Global Trade Uncertainty & Tariffs | Overseas sourcing is subject to unpredictable costs, risks, long lead times, and potential duties due to trade tensions. |

| North American Manufacturing / Reshoring | A strategic move for American companies to mitigate risks, stabilize costs, and build supply chain resilience by sourcing locally. |

| Foam Creations Expertise | Specializes in high-quality EVA Foam Injection Molding and Closed Cell Foam (including XL EXTRALIGHT® material) manufacturing located strategically in North America. Offers end-to-end services from design to production. |

| USMCA Advantage | Manufacturing within the USMCA territory (Canada/Mexico) can provide American companies with significant benefits, including potential tariff-free access to the US market. |

| Key Partnership Benefits | Partnership offers reduced transportation/warehousing costs, faster lead times, increased manufacturing flexibility, mitigated tariff risks, and high-quality local production. Access to specialized materials and design expertise. |

Conclusion: Partnering for Success in North American Manufacturing

For American businesses aiming to significantly enhance their supply chain reliability, effectively reduce operating costs impacted by global logistics and tariffs, and comprehensively mitigate international tariff risks, reshoring and sourcing critical components and products from North American manufacturers like Foam Creations is not merely an option; it is a powerful, strategic solution for the current global economic climate. Our deep expertise in closed cell foam solutions and advanced EVA foam injection molding technologies, combined with the undeniable strategic advantages of manufacturing within the USMCA territory in both Canada and Mexico, offers a clear and actionable path forward. This partnership facilitates streamlined operations, provides access to high-quality, specialized materials like XL EXTRALIGHT®, enables closer collaboration on design and manufacturing processes, leads to increased competitiveness in the market, and most importantly, provides potential tariff-free access to the crucial US market for your components and finished products. Choosing to partner for North American manufacturing is an investment in building a more resilient, predictable, and ultimately stronger supply chain capable of navigating future global uncertainties.

If you are interested in learning more about how Foam Creations can help your business achieve these benefits with high-quality closed cell foam solutions and strategic North American manufacturing capabilities, please contact us today to discuss your specific needs. You can also learn more by visiting our dedicated North America page, exploring our portfolio of successful projects, or checking out our latest news and insights.

Copyright © 2025 Foam Creations